Characteristics of a 2.5 layers forming fabric

2023-10-16

A 2.5 layers forming fabric is a type of fabric used in the papermaking process as a forming wire on the paper machine. It is an essential component of the paper machine that helps in the formation of the paper sheet from the pulp slurry.

Key features and characteristics of a 2.5 layers forming fabric include:

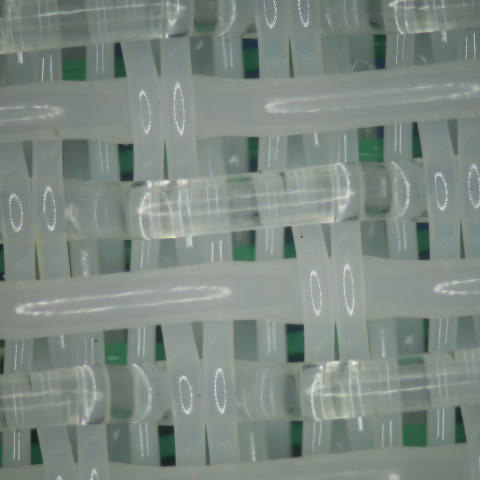

1. Construction: A 2.5 layers forming fabric is made up of multiple layers of woven mesh. It typically consists of two main wear layers, known as "top" and "bottom" layers, and an additional half-layer in between, hence the term "2.5 layers." The top and bottom layers are woven with larger diameter yarns for better wear resistance, while the half-layer has smaller diameter yarns to enhance the fabric's drainage capabilities.

2. Stability: The fabric is designed to have good stability, strength, and dimensional stability to withstand the high tension and stress encountered during papermaking.

3. Air Permeability: The 2.5 layers forming fabric has controlled air permeability, which is crucial for water drainage during the paper formation process.

4. Mesh Pattern: The fabric has a specific mesh pattern with openings that allow water to drain while retaining the fibers to form the paper sheet.

5. Seam Type: Forming fabrics are looped around the paper machine's rolls and joined with a seam to form an endless belt. The seam type used for the fabric depends on the specific requirements of the paper machine and the fabric design.

6. Material: Forming fabrics are typically made from synthetic materials like polyester or polyamide (Nylon) due to their high strength, durability, and resistance to chemicals and moisture.

Forming fabrics play a critical role in the papermaking process, as they help control the drainage of water from the pulp slurry, aid in fiber retention, and influence the formation and quality of the paper sheet. The unique design of the 2.5 layers forming fabric allows for efficient water removal while maintaining excellent fiber support and retention.

The choice of the forming fabric and its design depends on factors such as the paper grade being produced, machine speed, pulp characteristics, and other process-specific requirements. Proper maintenance and periodic replacement of forming fabrics are essential to ensure consistent and high-quality paper production.