Common types and methods of hydrogen generation

2023-10-16

A hydrogen generator system, also known as a hydrogen generation system or hydrogen production system, is a device or setup that produces hydrogen gas through various methods. These systems are used in a wide range of applications, including industrial processes, energy storage, fuel cells, and more. Here are some common types and methods of hydrogen generation:

1. Electrolysis: Electrolysis is a widely used method for hydrogen generation. It involves passing an electric current through water, splitting it into hydrogen and oxygen gases. Electrolysis can be performed using different electrolytes, such as alkaline, proton exchange membrane (PEM), or solid oxide electrolytes.

2. Reforming: Reforming processes involve converting hydrocarbon-based fuels, such as natural gas, methanol, or ethanol, into hydrogen gas. Steam reforming, partial oxidation, or autothermal reforming are commonly employed methods for hydrogen production through the reforming process. These methods involve reacting the fuel with steam or oxygen at elevated temperatures to produce hydrogen-rich gas.

3. Solar Hydrogen Production: Solar hydrogen production utilizes solar energy to generate hydrogen gas through various techniques. These methods include direct water splitting using photovoltaic cells or concentrated solar thermal energy, which drives high-temperature chemical reactions for hydrogen production.

4. Biomass Gasification: Biomass gasification is a process where organic materials, such as agricultural waste, wood chips, or energy crops, are converted into hydrogen gas through thermal or chemical reactions. This process involves heating the biomass in an oxygen-limited environment, producing a syngas that can be further processed to extract hydrogen.

5. Biological Hydrogen Production: Biological processes, such as fermentation or biophotolysis, involve using microorganisms or algae to produce hydrogen gas. These methods utilize the metabolic activities of certain microorganisms or the photosynthetic capabilities of algae to generate hydrogen as a byproduct.

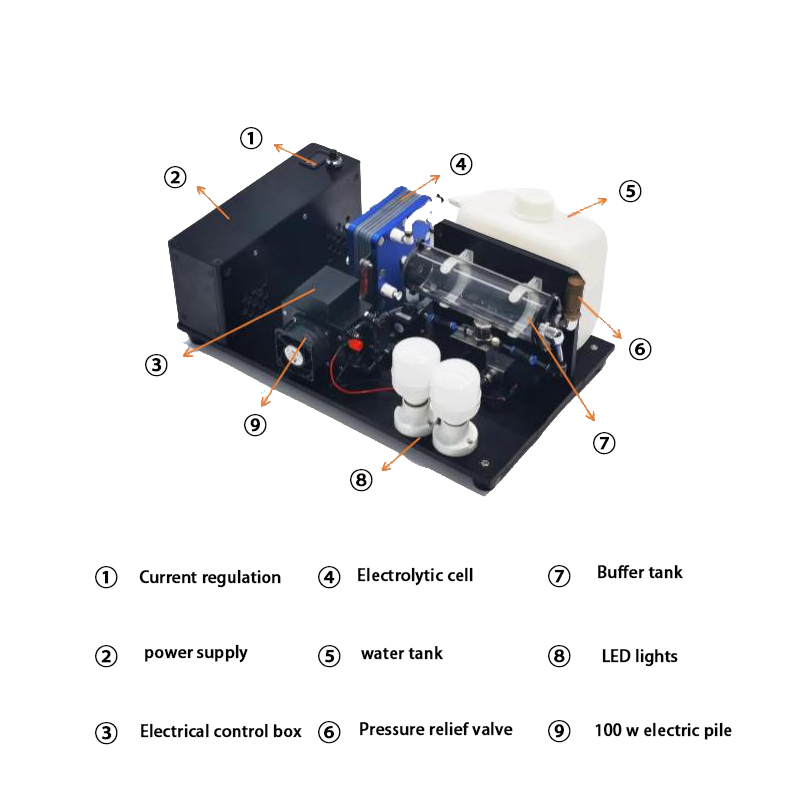

Hydrogen generator systems can vary in size, capacity, and complexity depending on the specific application and hydrogen demand. They may incorporate additional components such as gas purification units, compression systems, storage tanks, and control systems to ensure safe and efficient hydrogen production and utilization.

Hydrogen generated from these systems can be used as a clean and versatile energy source for various applications, including fuel cell vehicles, stationary power generation, chemical processes, and more. It is important to note that the choice of hydrogen generation method depends on factors such as cost, efficiency, scalability, environmental impact, and the specific needs of the application.