How Do You Choose the Right Rubber Gasket for Your Application

2025-04-17

When it comes to sealing performance choosing the right rubber gasket can make a huge difference. But how do you make the right choice for your application

The first step is to consider the working environment. Will the gasket be exposed to oil, heat, water, or outdoor weather Each type of rubber has different strengths. Silicone rubber gaskets handle high temperatures well while neoprene offers good resistance to weather and aging. Nitrile rubber gaskets are best for oil and fuel exposure, making them a popular choice in automotive and industrial applications.

Another factor is pressure and temperature resistance. High-pressure systems require strong and durable gaskets that do not deform under stress. Similarly, high or low temperature environments demand rubber materials that retain flexibility without cracking or melting.

The type of fluid or gas in your system also matters. For chemical processing systems or food-grade environments you will need a rubber gasket that is non-reactive and compliant with industry safety standards.

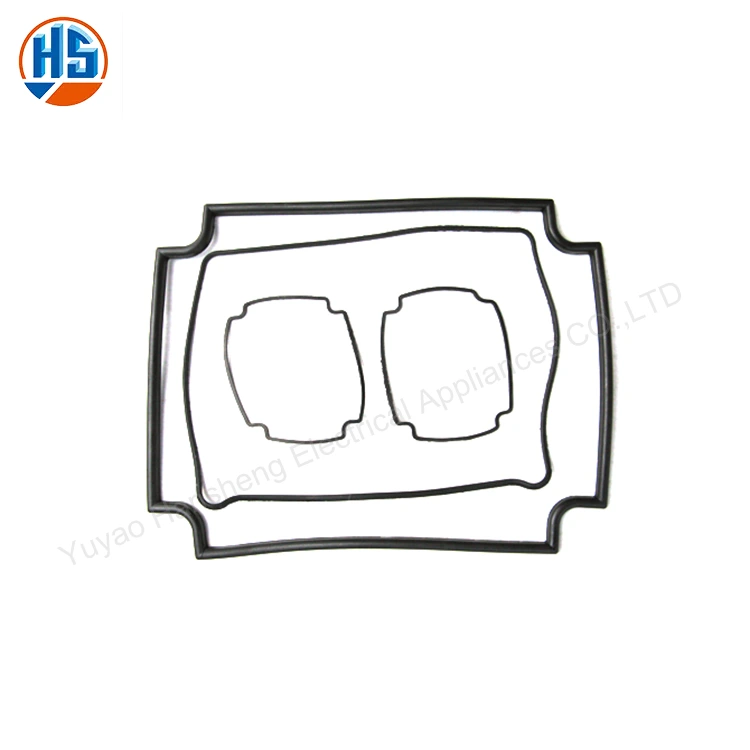

Do not forget about gasket size and design. Whether you need a flat gasket, O-ring, or custom-molded rubber part make sure it fits tightly to avoid leaks or equipment damage.

Choosing the best rubber gasket means balancing performance durability compatibility and cost. Whether for plumbing engines or factory equipment a properly selected gasket helps reduce downtime extend equipment life and improve safety.

Target Keywords: choose rubber gasket, best gasket material, oil-resistant rubber gasket, chemical resistant gasket, high temperature gasket, rubber sealing solution